|

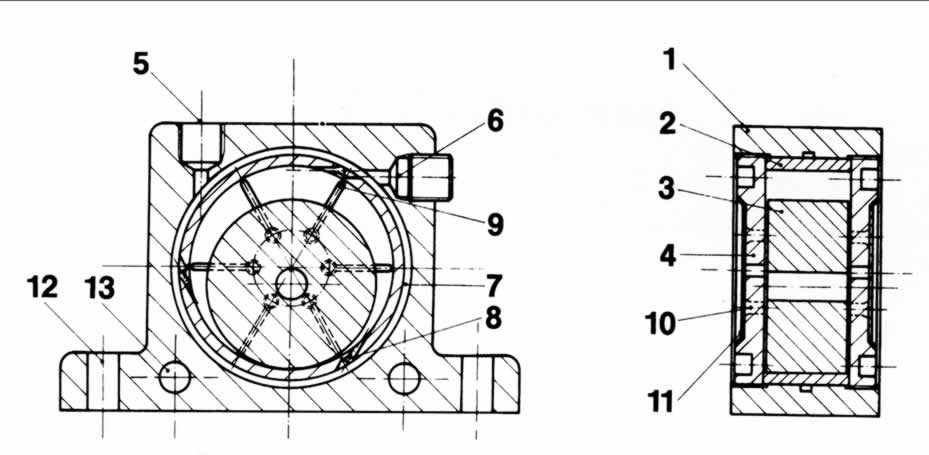

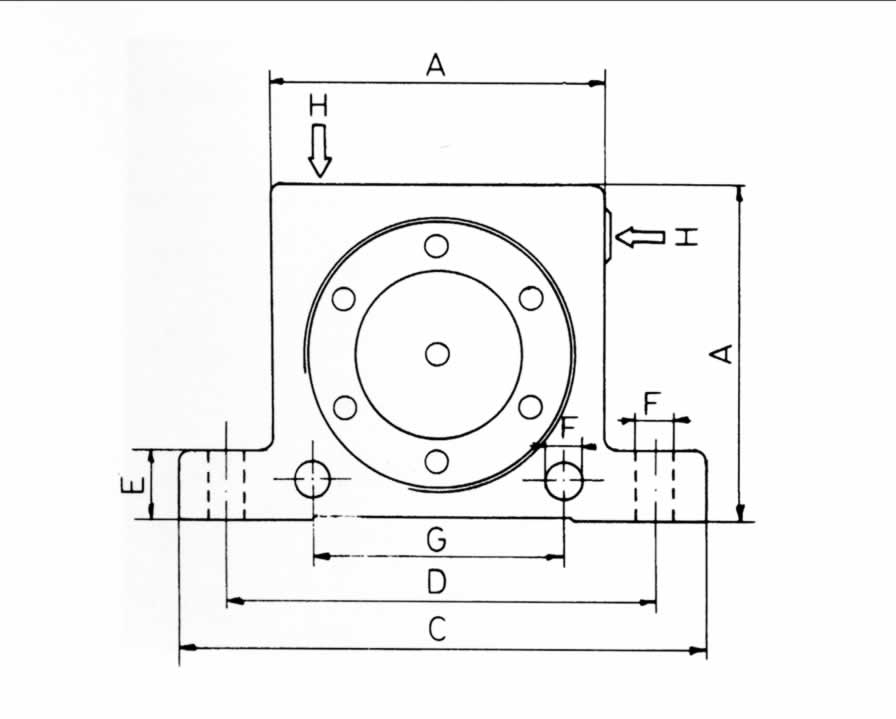

DESCRIPTION The R-Roller Vibrator is capable of delivering a very high amplitude (vibrator’s up/down movement). Air inlet can be mounted on the top (standard) The elliptical roller is retained by two special high impact plastic end plates. The housing is machined from an extruded aluminum section.

|

| PERFORMANCE | |||||||||

| MODEL | FREQUENCY | FORCE OUTPUT | AIR CONSUMPTION | ||||||

| 30 PSI | 60 PSI | 90 PSI | 30 PSI | 60 PSI | 90 PSI | 30 PSI | 60 PSI | 90 PSI | |

| vpm | vpm | vpm | lbs | lbs | lbs | cfm | cfm | cfm | |

R-50 |

12000 |

16000 |

18000 |

250 |

650 |

950 |

3 |

5 |

7 |

R-65 |

9000 |

11000 |

13000 |

600 |

1000 |

1300 |

7 |

10 |

14 |

R-80 |

7000 |

9000 |

11000 |

700 |

1300 |

1600 |

10 |

15 |

20 |

R-100 |

5000 |

7000 |

8000 |

850 |

1500 |

2000 |

13 |

19 |

25 |

R-120 |

4000 |

6000 |

7000 |

1200 |

1800 |

2400 |

17 |

25 |

34 |

. . |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPLICATIONS

|

TECHNICAL DATA |

|

| Unbalance Weight: | Cast iron asymmetrical roller |

| Lubrication: | Necessary (Oil ISO VG5 = 5cSt/40°C) or low viscosity air tool oil |

| Air Supply: | 30 to 90 PSI (2 to 6 bar) |

| Air Type: | Clean - Usage of a filter of 40 micron or lower is recommended |

| Body: | Aluminum, stove-enamelled blue |

| End Cap : | Plastic, threaded (Left and right hand) |

| Ambient Temperature: | 200°F (110°C) |

| Noise Level Range: | 85 to 100 dBA |

| Inlet type | BSP |